We are very excited to announce that effective October 1, 2017 we will be representing Precision Cutting Tools Inc. in the California and Nevada market areas. Precision Cutting Tools Inc. was founded in 1963 and ever since has specialized in the production of high-quality cutting tools. Today, with over fifty years of experience, PCT is a leading cutting tool manufacturer that distributes its products all across the United States and Mexico. They have based their company’s success on their long-standing commitment to satisfy our customers’ needs, by utilizing the finest raw materials, introducing innovative cutting tools and providing excellent customer service. We look froward to working with them to develop new Carbide, Cobalt & Powdered Metal end mill and drill substrates and geometries that will meet the material cutting needs we find uniquely on the West Coast. We think you are in for a a real treat once we see what we're working on with PCT!!!

0 Comments

Farewell & Parting: Next Generation Tooling ends relationship with MA Ford after 22 years.9/29/2017 After 22 years, Next Generation Tooling has ended our relationship as an independent sales agent for MA Ford in the Northern California and Northern Nevada territories. Our last effective day will be September 30, 2017.

We truly appreciate and greatly value our long, successful relationship fostered by both MA Ford and NextGen since the inception of our company. We realize, with no reservation, that the wonderful people at MA Ford were a huge part of our success by working with us to develop technical solutions and will always value our memories and our personal friendships. At the outset of our relationship in the late 1990's, we worked hand-in-hand with MA Ford to introduce their products to the unique applications and high speed machining that takes place in our markets. In conjunction with the MA Ford engineering team we developed the 138 series end mills for use in aluminum and non-ferrous milling. As a result, many other end mill manufacturer's followed in the footsteps of that tool and began developing material specific tooling. Because of the unique needs of our market, we suggested the expansion of LOC and OAL from what was commonly offered in "Stub, Standard, Long & Extra Long" lengths. The 138 series end mills where the first nationally recognized brand to offer 7 different lengths of cuts as stock standard. We are very grateful to everyone at the MA Ford team who has worked with us hand-in-hand for so many years, and wish only the best for MA Ford in the future.

We got to spend a few days in Chicago to get a great preview of some of the newest products and innovations for the kind of machining we do on the West Coast.

There's some really informative videos on quite number of the products so be sure and give yourself some time to watch them.

5th Axis - Duece Vise

Use as a single or double station fixed jaw vise. Two vises for the price of one.

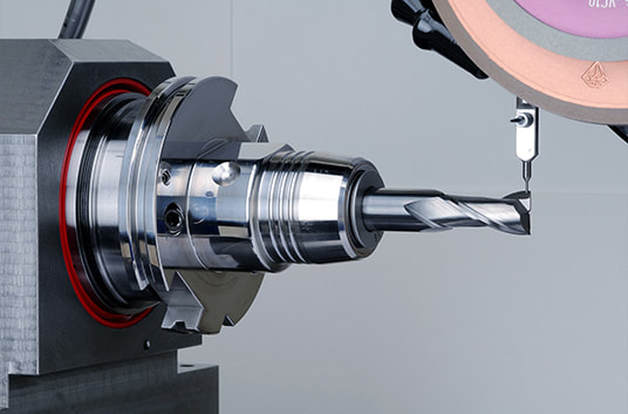

The small footprint allows for multiple units to be ganged together on vertical or horizontal machines. BIG KAISER - EWD EVO Digital Head EWD EVO digital boring head EWD EVO digital boring head

BIG KAISER is continuing down the path of digital tooling innovation with the introduction of the EWD EVO, a digital boring head designed with a single goal in mind—making the life of an operator as easy as possible.

It will be synched with the new BIG KAISER smartphone and tablet app, which was developed to enhance user friendliness while assembling and running BIG KAISER boring tools. Not only will you be able to read the cutting diameter change, but the app will also help operators determine optimal cutting parameters from their tool assemblies. The app will also log historical adjustments for all tools ever synched with it, a critical piece for shops joining the smart manufacturing movement. Heimatec Offers Machine Brand-Specific Tooling

Heimatec Inc. spotlighted its complete line of live tools and showcased them at IMTS in a series of four new catalogs. Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database,

MA Ford - CDA Aluminum Coolant Drill

MASA - F20M10 Cartridge

Check out the video! Matt Saccomanno discusses the Microconic Workholding system at IMTS 2016.

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine.

The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter. mPower - Spin Select

Read this section or just watch the video! The SpinSelect Multi-Pocket Selectable Tool Holder was created to increase productivity and consistency by decreasing downtime associated with tool and insert setups and changovers.

Designed for use on most lathes having a turret or tool post, SpinSelect™ offers significantly better throughput on machining tasks such as heavy roughing, harder material removal, and short runs. Machining operators have seen up to an 85% savings on changeover/setup times as SpinSelect creates a nearly continuous runtime with offline insert changes/reloading.

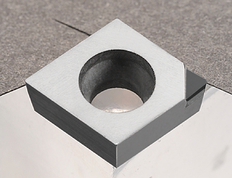

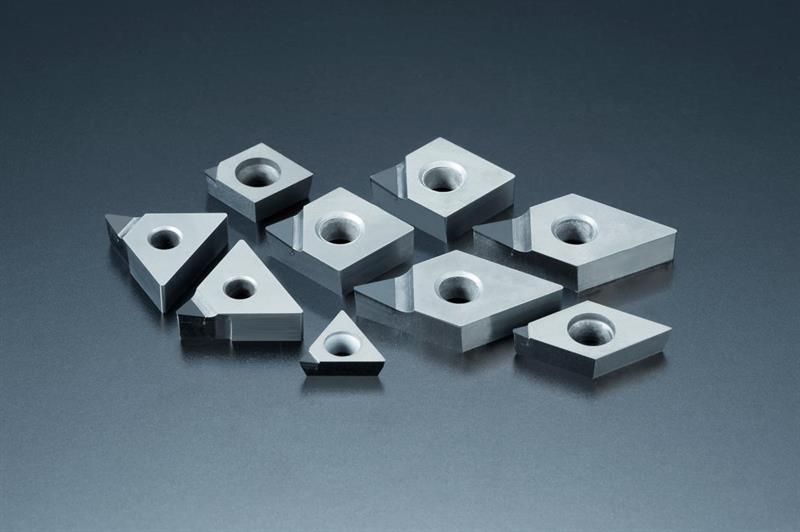

NTK - PD2 Super Micorgrain PCD Inserts

The high speed turning of aluminium alloys and non-ferrous materials has now been taken to a new level with the introduction of the NTK PD2 insert line. With exceptional edge sharpness and adhesion resistance, the new PD2 range of inserts are ideal for extending tool life and productivity on difficult to machine alloys.

Furthermore, the edge toughness and composition give the PD2 tool life and consistency that is unrivalled when conducting interrupted and continuous machining.  NTK PD2 PCD tipped Carbide Insert NTK PD2 PCD tipped Carbide Insert

The new PD2 is available as a positive insert with a CCMT, DCMT and TPMT geometry that provides a PCD cutting edge length of 2.3mm with the option of a 0.2 or 0.4mm corner radius. The various insert geometries and available with an insert thickness from 2.4 to 9.5mm.

Complementing the positive geometry inserts is a complete selection of negative type inserts for the PD2. The CNMX, DNMX and TNMX geometries have a cutting length of 3.4, 4.5 and 3mm respectively and all inserts have a 4.76mm thickness that promotes strength and rigidity. The three insert types are available with a corner radius of 0.4 or 0.8mm to prevent edge breakages and prolong tool life and consistency. Both the positive and negative type single cutting edge inserts are available with a range of toolholder designations to suit all types of turning centre from the smaller sliding head centres through to heavy duty turning machines. OSG - Exopro Aero Series for Composites

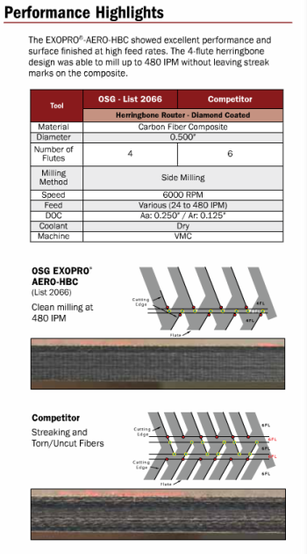

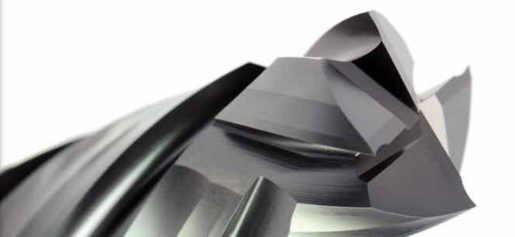

A variety of cutting tools exhibited included the new EXOPRO AERO end mill series for composites.

Ever dream of machining composites without delamination and tool life issues? Composites are constructed with layers of material that are prone to delamination. They are also known to be abrasive and could easily wear your tool down. If your tool loses its sharpness, the material gets pushed away instead of cut, producing uncut fibers. OSG’s EXOPRO® AERO-BNC routerovercomes these problems and even provides high feed roughing and a superior finish.

Longer Tool Life

The AERO-BNC also features OSG’s patented diamond coating which has a maximum diamond grain size diameter of 2μm. This ensures our coating is super smooth. Unlike our competition, we manufacture all diamond products in-house using our grinding technique on our special carbide substrate. This patented diamond coating coupled with the AERO-BNC router’s thick core diameter and multiple flutes extends tool life significantly. Improved part finish and sharper cutting edges are also the end results of the diamond coating. Versatility The AERO-BNC is extremely versatile and can be applied in both thick and thin laminates. It is versatile enough to handle trimming, slotting and shoulder milling applications! It also can engage parts by plunging, ramping or helical entry and is available in various end cuts to enable you to find the right tool for your job. Techniks - Hydraulic Holders

The MA Ford Series 138CE comes with the new CERAedge high performance ceramic coating! With a hardness that makes it the 3rd hardest material when compared to industrial diamonds! You can see the video of the 138CE below. What is CERAedge? CERAedge combines the heat resistance of conventional AlTiN coating with the hardness and smoothness of amorphous diamond coatings. It's a ceramic coating with extreme properties

The OSG AeroHBC is a herringbone style router for high feed rates and excellent surface finishes in difficult to cut carbon fiber composites and Nomex honeycomb sandwich materials. It features a compression cutting mechanism to reduce the tendency of flagging in honeycomb materials.  Upshear, Downshear and Herringbones We often get asked about the advantages of different types of cutters by machine shops who are starting to move from metals based machining to composites. Here's a short explanation. Upcut or upshear routers will pull the chips up and out of the cut. Most standard end mills and routers operate this way. Downshear routers leaves a crisper, cleaner edge on the top surface of the material because they push the chips downward into the material. Herringbone cutters, also called compression routers, combine the two for the cutting of laminates, honeycomb or any two sided material. It virtually eliminates chipping, or flagging, on both sides for cleaner edge surface finishes. It also prevents the delimitation of the surface materials that sandwich the honeycomb together. In a herringbone cutter the bottom portion is upshear and the top portion is downshear. The EXOPRO Aero-HBC Features EXOPRO® AERO-HBC Features

Applications

Benefits

DiACON, a part of M.A. Ford’s Advanced Product Group, features a wide range of high performance, polycrystalline diamond (PCD) tipped tools to improve your productivity in today’s metal, wood and composite material industries. PCD tooling is ideal for more efficient machining of non-ferrous metals, plastics, composite materials, graphite and other hard to machine and abrasive materials. DiACONTM offers end mills, drills, step drills, step reamers and countersinks. Special tools are quoted upon request. According to MA Ford, "DiACONTM is dedicated to continually developing innovative products manufactured with efficient state-of-the-art technology while offering great value and top quality at reasonable prices." The tools will be offered in the following standard configurations. Here are the series names and some information about them.

Here's some of the details on the new tools:  DES (DiACON End Mill Square) Series A straight flute PCD tipped end mill available with 1 or 2 flutes depending on tool size and configuration. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials. A straight flute PCD tipped end mill available from 3 flute to 9 flutes depending on tool size and configuration. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials.  DEB (DiACON End Mill Ball) Series A straight flute PCD tipped ball nose end mill available in 1 or 2 flutes depending on tool size. These end mills combine a PCD tip with a carbide body for maximum rigidity and optimal performance. Offers excellent results in CFRP (Carbon-Fiber- Reinforced Polymer), fiberglass, aluminum and other very abrasive materials.  DSE (DiACON Spiral End Mill) Series A spiral veined PCD end mill designed with a 30 degree helix (15 degree helix angleavailable as a special). Available in 2 flute for 6mm and 1⁄4” diameters, and 4 flute for larger diameters. A through hole can also be provided as a special on sizes 3/8” (10mm) and above. Offers excellent results in CFRP (Carbon-Fiber-Reinforced Polymer), fiber-glass, aluminum and other very abrasive materials.  84PCD Series A two flute PCD tipped microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. Available in inch and metric sizes and also can be reconditioned for maximum cost per hole.  87PCD Series A three flute PCD tipped microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. The three flute design allows for optimal wear resistance. Available in inch sizes and also can be reconditioned for maximum cost per hole.  83PCD Series A two flute PCD tipped integral pilot microstop countersink manufactured on a high speed steel body allows for exceptional performance in aircraft composite applications. Available in inch and metric sizes. Due to the integral pilot design, tools are not typically reconditioned, but can be quoted if needed.  DWD (DiACON Spiral Wafer Drill) The spiral wafer drill offers excellent performance in CFRP (Carbon-Fiber-Reinforced Polymer), fiberglass, aluminum and other very abrasive materials. Available as a special from 1/8” to 1/2” and 3mm to 16mm.  DND (DiACON Nib Drill) Series DiACONTM’s Full Nib Drill has been specifically developed for the drilling of CFRP and CFRP/Metal stack used on all modern aircraft today. The high performance point and fluting geometry greatly reduces separation and delamination in the drilling process. The DiACONTM Full Nib Drill can also be reconditioned two to three times for improved cost per hole. Available as a special in sizes from 1/8” to .354” and 3mm to 10mm. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed