|

As BIG KAISER celebrates 30 years, Chris Kaiser reflects on running a company from home again. It’s been 30 years since I started KAISER Precision Tooling USA, and I never imagined I’d be running this company from home again. Like most BIG KAISER employees, I’m working remote at least a few days each week to maintain the required social distance. I can relate to the experience many are having now as they juggle work and family at literally the same time. Isn’t this the experience of parents everywhere who are also entrepreneurs working to start a new business? Back in 1990, after living and working in the U.S. for nearly a decade, I started this company out of necessity. I knew we needed to change how we were selling the boring tools manufactured by my father’s company in Switzerland, Heinz Kaiser AG. I had a vision to increase sales with better marketing, product deliveries and customer service, but my goals weren’t shared by the agents and partners we had at that time. That’s how I found myself sequestered at home with two little boys regularly knocking on the door asking when I was going to come out and play. As much as I wanted to do that, I also needed to focus on setting up a new company from scratch. There was no building, no equipment, no staff. Many late nights were spent working with a friend in his basement, writing a business plan, setting up systems for accounting and IT, and making the first boring tool catalog. During the day I sought legal advice, met with lenders and looked for a facility that would house this new company. In July of that year, I was joined by my long-time partner, and now BIG KAISER Vice President, Jack Burley. Operations Manager Tim Grosch also started in that first year. There were many other friends and influential people along the way, but these two have been with me on this adventure since the very beginning. On August 1, 1990 – coincidentally also Swiss Independence Day – we opened the doors at our first facility in Elk Grove Village, IL. It was two minutes from my house so I could spend a lot of late nights at work, after dinner with my family, just as my father did when I was little. After 30 years, I’m proud to say we’ve had a good number of customers from the very beginning. Possibly the first was a Swiss-born machinist who carried Heinz Kaiser boring tools back from his vacation in Zurich to his job in the repair center at United Airlines in San Francisco. United remains a customer of BIG KAISER today. Some of those old boring tools are repairable and still in service. Many U.S. companies in defense and other industries bought SIP jig-boring machines made in Geneva, Switzerland. They also invested in precision boring tool kits – packed in a wooden case – from Heinz Kaiser AG. We’re grateful that companies like Bell Helicopter, Sikorsky, Caterpillar, John Deere, Metalex, Vermeer and Viking Pump – among others – are still with us to this day. I look forward to reuniting with long-time customers, partners and friends at a 30th anniversary celebration sometime later this year. In the meantime, I hope we can all get back to the office and a more normal routine very soon. Seeing my grandson on FaceTime and Zoom is just not as good as going outside to play!

Until then, stay well and stay positive. Chris Kaiser Is there any chance someone has a PICCOLO boring tool in the original wooden box from that time? I would love to have a photo of it.

0 Comments

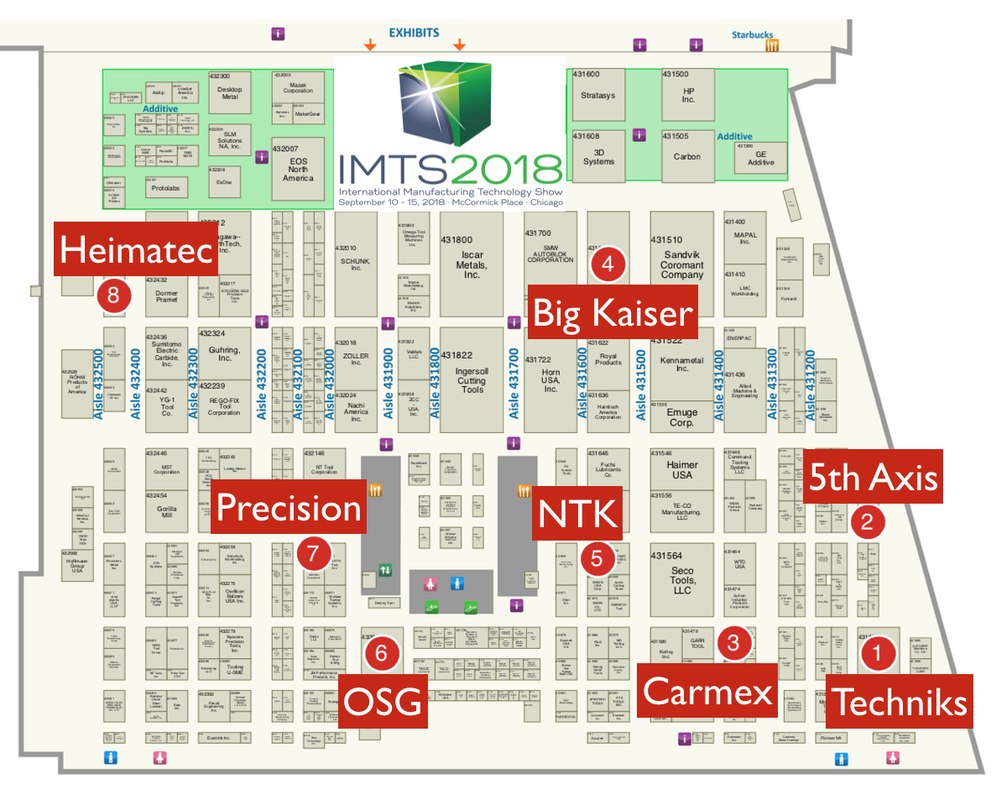

Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075

We got to spend a few days in Chicago to get a great preview of some of the newest products and innovations for the kind of machining we do on the West Coast.

There's some really informative videos on quite number of the products so be sure and give yourself some time to watch them.

5th Axis - Duece Vise

Use as a single or double station fixed jaw vise. Two vises for the price of one.

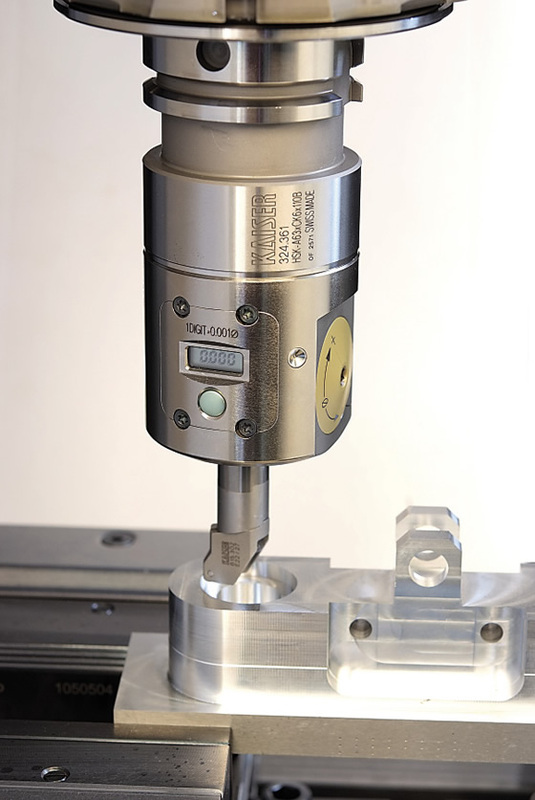

The small footprint allows for multiple units to be ganged together on vertical or horizontal machines. BIG KAISER - EWD EVO Digital Head EWD EVO digital boring head EWD EVO digital boring head

BIG KAISER is continuing down the path of digital tooling innovation with the introduction of the EWD EVO, a digital boring head designed with a single goal in mind—making the life of an operator as easy as possible.

It will be synched with the new BIG KAISER smartphone and tablet app, which was developed to enhance user friendliness while assembling and running BIG KAISER boring tools. Not only will you be able to read the cutting diameter change, but the app will also help operators determine optimal cutting parameters from their tool assemblies. The app will also log historical adjustments for all tools ever synched with it, a critical piece for shops joining the smart manufacturing movement. Heimatec Offers Machine Brand-Specific Tooling

Heimatec Inc. spotlighted its complete line of live tools and showcased them at IMTS in a series of four new catalogs. Already offering the most complete line of live tools available in the industry, with over 40,000 designs in its database,

MA Ford - CDA Aluminum Coolant Drill

MASA - F20M10 Cartridge

Check out the video! Matt Saccomanno discusses the Microconic Workholding system at IMTS 2016.

Masa Tool has developed the Microconic™ system specifically for holding workpieces from Ø0.15mm to 10mm (Ø0.006" to 0.390") in any machine that has a collet-type chuck.

The Microconic™ system works with either draw-type or push-type standard collet systems that are in any machine.

The Over-grip collet capabilities of Masa Microconic™ System, introduces a whole new world of time saving opportunities awaiting. Our Overgrip Collets open up to 4mm (0.157") diameter larger than the clamping diameter. mPower - Spin Select

Read this section or just watch the video! The SpinSelect Multi-Pocket Selectable Tool Holder was created to increase productivity and consistency by decreasing downtime associated with tool and insert setups and changovers.

Designed for use on most lathes having a turret or tool post, SpinSelect™ offers significantly better throughput on machining tasks such as heavy roughing, harder material removal, and short runs. Machining operators have seen up to an 85% savings on changeover/setup times as SpinSelect creates a nearly continuous runtime with offline insert changes/reloading.

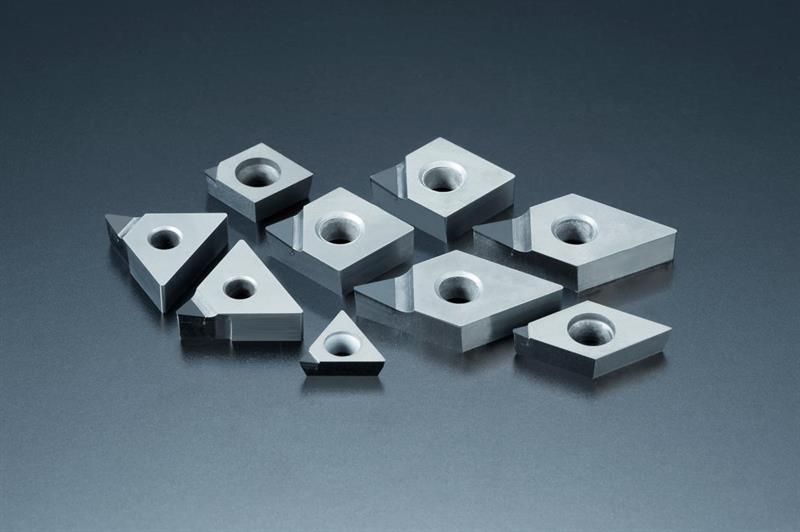

NTK - PD2 Super Micorgrain PCD Inserts

The high speed turning of aluminium alloys and non-ferrous materials has now been taken to a new level with the introduction of the NTK PD2 insert line. With exceptional edge sharpness and adhesion resistance, the new PD2 range of inserts are ideal for extending tool life and productivity on difficult to machine alloys.

Furthermore, the edge toughness and composition give the PD2 tool life and consistency that is unrivalled when conducting interrupted and continuous machining.  NTK PD2 PCD tipped Carbide Insert NTK PD2 PCD tipped Carbide Insert

The new PD2 is available as a positive insert with a CCMT, DCMT and TPMT geometry that provides a PCD cutting edge length of 2.3mm with the option of a 0.2 or 0.4mm corner radius. The various insert geometries and available with an insert thickness from 2.4 to 9.5mm.

Complementing the positive geometry inserts is a complete selection of negative type inserts for the PD2. The CNMX, DNMX and TNMX geometries have a cutting length of 3.4, 4.5 and 3mm respectively and all inserts have a 4.76mm thickness that promotes strength and rigidity. The three insert types are available with a corner radius of 0.4 or 0.8mm to prevent edge breakages and prolong tool life and consistency. Both the positive and negative type single cutting edge inserts are available with a range of toolholder designations to suit all types of turning centre from the smaller sliding head centres through to heavy duty turning machines. OSG - Exopro Aero Series for Composites

A variety of cutting tools exhibited included the new EXOPRO AERO end mill series for composites.

Ever dream of machining composites without delamination and tool life issues? Composites are constructed with layers of material that are prone to delamination. They are also known to be abrasive and could easily wear your tool down. If your tool loses its sharpness, the material gets pushed away instead of cut, producing uncut fibers. OSG’s EXOPRO® AERO-BNC routerovercomes these problems and even provides high feed roughing and a superior finish.

Longer Tool Life

The AERO-BNC also features OSG’s patented diamond coating which has a maximum diamond grain size diameter of 2μm. This ensures our coating is super smooth. Unlike our competition, we manufacture all diamond products in-house using our grinding technique on our special carbide substrate. This patented diamond coating coupled with the AERO-BNC router’s thick core diameter and multiple flutes extends tool life significantly. Improved part finish and sharper cutting edges are also the end results of the diamond coating. Versatility The AERO-BNC is extremely versatile and can be applied in both thick and thin laminates. It is versatile enough to handle trimming, slotting and shoulder milling applications! It also can engage parts by plunging, ramping or helical entry and is available in various end cuts to enable you to find the right tool for your job. Techniks - Hydraulic Holders

This article originally appeared in the May 2013 / Volume 65 / Issue 5 of Cutting Tool Engineering titled "Evolving toward digital" By Matt Tegelman, BIG Kaiser Precision Tooling Inc. Boring tools with a digital readout aren’t the standard in U.S. shops, but their use is growing.Think about the number of digital equipment interfaces and interactions an operator has when machining. Machine operators use keypads and computers to run tooling programs and measure parts with digital gages and coordinate measuring machines. By definition, CAD/CAM work is accomplished digitally. Machine tool controls have digital displays. On most tool presetters—even simple ones without a vision system—the readout is digital. Bore gages are digital, whether it’s an air gage or a three-point-contact gage. There are still a few old-timers who trot out ID micrometers once in awhile, but most measurement devices are digital for speed and accuracy.

Still Kicking Analog readout technology isn’t dead because it’s still highly effective for the majority of low- to medium-level tolerance operations. Few shops have yet to make the switch to digital boring across the board, and it will be a long time before more do so on a regular basis. Digital boring heads cost 60 to 80 percent more than their analog counterparts. That said, as old boring heads need replacement and more operators become accustomed to the advantages of digital boring adjustments, there eventually will be a turning point in some operations where it makes sense to go all digital. This change won’t happen just because it’s the direction of the industry.

Don’t Sacrifice PerformanceIf a shop is considering moving from analog to digital boring tools, the best conversions are those that can be accomplished without having to replace any accessories—simple one-for-one boring head trade-offs. Still, ask questions to ensure this is the case with your shop. Users can defeat the purpose of digital ease of use if the head isn’t a 1:1 replacement and additional programming or tinkering is necessary when converting to digital. For instance, Kaiser’s 112 EWD, 310 EWD and 318 EWD digital boring heads are otherwise identical to their analog predecessors. They have the same boring ranges, cutting parameters and through-coolant capabilities, so an operator can swap an analog for a digital model with little or no reprogramming. All three series use the same accessories, such as boring bars and insert holders, as their nondigital counterparts.

Despite the obvious advantages of digital, the technology isn’t yet for everyone. But as manufacturing and technology continue to become more and more entrenched in the digital realm, there will be a tipping point after which digital boring is the norm. Some shops will just be ahead of the curve. CTE

About the Author: Matt Tegelman is the Kaiser product manager for BIG Kaiser Precision Tooling Inc., Hoffman Estates, Ill. For more information about the company’s boring tools and other products, call (888) TOOL-PRO or visit www.bigkaiser.com. Digital boring heads from Big Kaiser were designed to be a simple 1:1 match to their analog predecessors - same boring ranges, cutting parameters, and through-tool coolant capabilities - so an operator can swap an analog for a digital model with little or no reprogramming. Just like your cell phone or computer, it won't be long until you wonder how you ever lived without a digital interface. Make the leap to digital technology. WHY DIGITAL?

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed