|

+1Axis Indexer allows you to easily and economically add another axis to your machining. The +1Axis Indexer is adjustable in 15° increments and is compatible with the Techniks DV-075 Dovetail Vise, the 5th Axis D-22 Dovetail Fixture and the Raptor RWP-024 and RWP-024SS Dovetail Fixtures. You can now perform accurate 3+1 index machining on 3-axis machines for one workpiece or multiple positions across a fixture plate. On a 4-axis machine you can perform 4+1 axis machining in a single part setup or, if mounting multiple +1Axis Indexers on a rotary tooling block, you can perform 4+1 machining on several parts gaining access to 5 sides of the workpiece. Using the +1Axis indexer on a 5-axis machine allows access to workpiece faces that are unreachable on common pyramid riser block setups.

0 Comments

Cleveland, OH - Jergens Inc. is pleased to announce the official launch of our new and improved tooling and workholding website! How to Navigate the NEW Jergens Website:Ready to check it out for yourself? Just CLICK HERE!

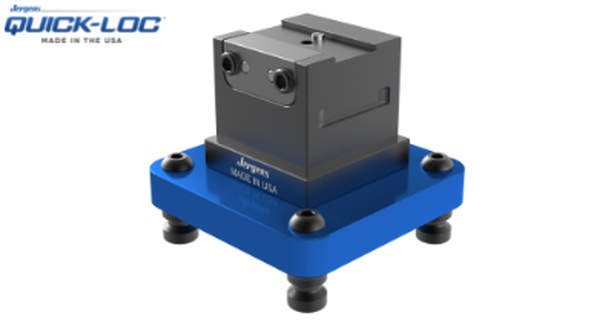

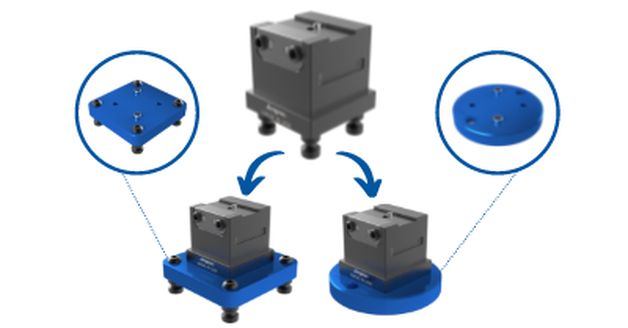

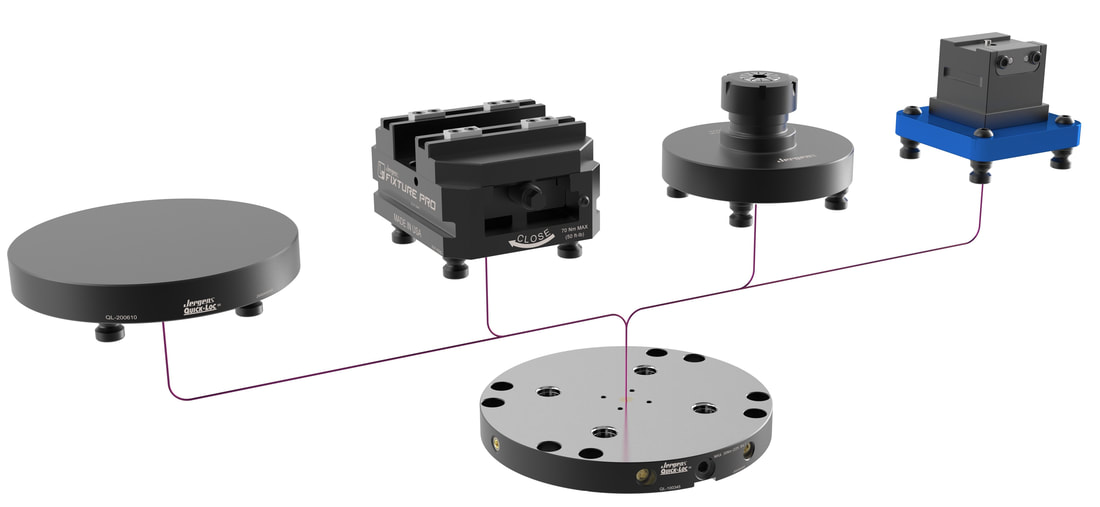

Why dovetail workholding? Dovetail workholding is unique and ideal for holding workpieces that require larger metal removal, and multiple machining passes and operations. The puzzle-piece connectivity provides maximum holding strength with minimum material contact. That means that more of the part is accessible, which is even more advantageous when addressing complex components within limited machining envelopes. All that’s required are a few simple passes with minimal metal removal and your workpiece is ready to grip for a multitude of operations. (Machining) Five Sides on Five-Axis Machining One of the key benefits of dovetail workholding is the unique underneath grip that provides the greatest access to workpieces, making it possible for true five sides machining. Furthermore, dovetails are a versatile solution that can hold a greater variety of parts, in effect reducing the need for custom fixtures and allowing you to standardize on a clamping method and equipment across a wide variety of workpiece types and sizes. Why Jergens? With Jergens Fixture Pro®, you can take the next step in productivity by adding quick-change to the equation. A new group of modular dovetail vises and adapter bases ensures secure clamping and provides Jergens repeatable quick-change solution so you can spend more time in the cut and less time in part changeover. The combination of this type of high-strength workholding with these new modular vises represents a dramatic decrease in overall setup and cycle times. Here's how the math adds up. Part Security + Increased Accessibility + Quick-Change + Number of Parts = Next Level Productivity. Level one: For every securely fixtured workpiece, more operations can be performed without the need to index or reorientate because so much of the workpiece is unencumbered. Level two: When the workpiece needs to be repositioned or changed to the next one, it is done via one of two high-speed changeover solutions - Quick-Loc™ or QLS. Level three: In the case of QLS, several workpieces are loaded along multi-sided columns taking advantage of available vertical (or horizontal) space, filling the machining envelope with numerous parts, and all of those are quick-change as well. Workpieces stay securely clamped in the dovetail vise and adapter base during the changeover to facilitate immediate reloading and secondary operations as needed. Of the new vises, two are engineered with Jergens Quick-Loc™ pallet system and include industry-standard patterns 52mm and 96mm. With a single drive screw, Quick-Loc™ provides fast and repeatable fixture changes for small tooling platforms. A square aluminum adapter base provides the connection to either of the two patterns. A third vise features Jergens Quick Locating System (QLS) mount, for column-mounting possibilities, and a corresponding round adapter base.

|

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed