|

by Doug Sumner, BIG DAISHOWA—Americas Successful shops always look for ways to differentiate and innovate for competitive advantage. Cashing in on the entirety of a tool’s life with an advanced tool management system is perhaps the most effective way to do that right now. Go with me for a minute. Think of a single tooling component’s trip through a shop in terms of a life: it’s conceived when it’s ordered from a supplier and born and finds its way to the tool crib; it grows up in the bin and finds its perfect mate when it’s assembled; it does good work on the job, cutting metal and eventually rides off into the sunset, aka the scrap bin. RIP tool. You lived a good life. All kidding aside, notice how little of the tool’s journey through the shop is spent actually cutting metal? As in life, one’s career is just one of many factors in a happy life. In this case, the actual time the tool is cutting accounts for a fraction of its impact on the shop. Acquisition, inventory management, assembly, travel across the floor, wear and dispensing of a tooling component, they all happen with a certain efficiency – or inefficiency – and have a value. Shops know how much of their purchasing budget goes to tooling, but few know how much value is gained or lost while it’s in the shop. This is where tool management systems (TMS) come in. Every company has a TMS of some sort, whether it’s the tool room manager’s chicken scratch on a printed excel sheet or wirelessly tracking components as they move across a shop and automatically managing inventory based on their usage. Based on my travels, the chicken scratch method, or some slight variation of it, is far more common today. But things are changing. The rise of Smart Manufacturing is exposing the immense savings available while the more connected floor is making them more accessible. It’s drawing a stark distinction between reactionary chicken scratch- and proactive hyper traceability-TMS. The risk of a reactionary system is finding out the value of the tool’s journey the hard way. Consider the following scenarios. A job makes its way from engineering and planning to the tool room. They discover they don’t have a certain insert or have just enough to start, but not to finish, and the stock sits until the insert arrives. That’s wasted spindle time, perhaps delayed delivery – maybe even paychecks – because of a missing insert that costs a few bucks. The other side of that coin is ordering more cutters just because the bin looks low and not having a job in the pipeline that requires them. That’s cash burning a hole in the tool shelves. If you have an offline tool measuring system, you’ve already taken the first steps toward more efficient tool management. Sure, tool presetters reduce setup time and tooling costs by eliminating error and adding precision, but now they can also act as a shop communication hub. Our most sophisticated, and frankly most consistently successful customers, use Speroni tool presetters equipped with software that communicates with the engineer’s CAM software to verify length, diameter, create a G-Code and post process with the exact tooling values. This type of arrangement is just scratching the surface. And believe it or not, suppliers have been working to get us to where we are for decades. Our Italian partner, Speroni, started working with Fiat automotive manufacturing more than 30 years ago, connecting tool rooms to the rest of the manufacturing facility. Today, most solutions are optimized for management, often without much flexibility to adapt to what’s happening on the floor or what may happen there next year. Having made our name in tooling – as far down in the weeds as you can get in a metalworking operation – we’ve worked with Speroni to apply a different philosophy to connectivity and traceability to our North American customers. Our solution, Intelligo, focuses on where everything is happening: the shop floor. Its processes are fed by using devices that recognize components, cutting edges, tool assembly, carts, baskets, etc. through wireless systems (i.e. RFID or QR/barcode) as they travel the shop. SPERONI INTELLIGO Tool Management Solution software allows you to comprehensively organize your tool assemblies, your individual components, plus your tool jobs and kits in a central knowledge database avoiding redundant data. Using a scalable software structure and local workstations, Intelligo links a company’s entire tool library, active or inactive, with the CAM, planning and measuring software and displays it in a 3D graphic interface for visual reference in real time. Visibility and tracking of the floor’s activity allows a shop to proactively manage consumable inventory, consumption and assembly, preventing downtime and enhancing profitability. You can monitor how tools wear on certain jobs and adjust. Or, if duplicate machines deliver different productivity on the same job, you can easily identify the exact tools used and find out what’s causing the discrepancy and diagnose machine or spindle issues. It’s even possible to determine a machine tool’s consumption in terms of discarded components following a particular production process. That’s not to mention the opportunity floor-up tracking and data provides to optimize tool regrinds, QA, raw material, fixturing – even the scrap bin, since it’s a profit center. This level of TMS may be a world away from how most manufacturers operate today, but for most it’s not that far out of reach. Installation is hands-on and cooperative, and most shops do have the fundamental infrastructure to support it. This train isn’t stopping. The technology is here, readily available and quickly making excuses like “it costs money and doesn’t make chips” or “this is the way we’ve always done it” obsolete. Shop and process connectivity is the direction metalworking is headed and I believe a floor-up approach is the best approach.

Now is the most profitable time to get on board, before everyone else is. Successful shops are always looking for ways to differentiate and innovate, and cashing in on the entirety of a tool’s life with advanced TMS is perhaps the most effective way to do that right now.

0 Comments

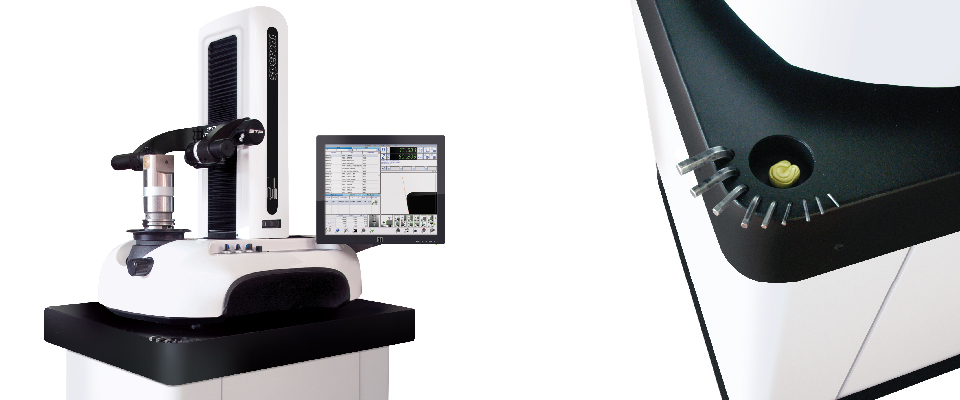

Entry-level Tool Presetting and Measuring system Big Daishowa’s Speroni STP Essentia tool presetting and measuring system performs measurements next to machine tools. The SPERONI STP ESSENTIA is the entry-level Tool Presetting and Measuring system. Its robust structure and user-friendly software interface allow customers to benefit from a basic, essential unit with a tangible, long-lasting performance. The ESSENTIA enables users to measure tools offline and has user-friendly controls designed to optimize tool measurement operations. The MaxP runout function, base post processor and entry-level tool database are included in the Essentia control. Presetters measure the cutting edges of tools to ensure they match job specifications and are ready for use in the machine. Adjustments that could take up to 15 minutes can be made offline in less than one minute on a presetter, the company says, allowing the machine to continue cutting.

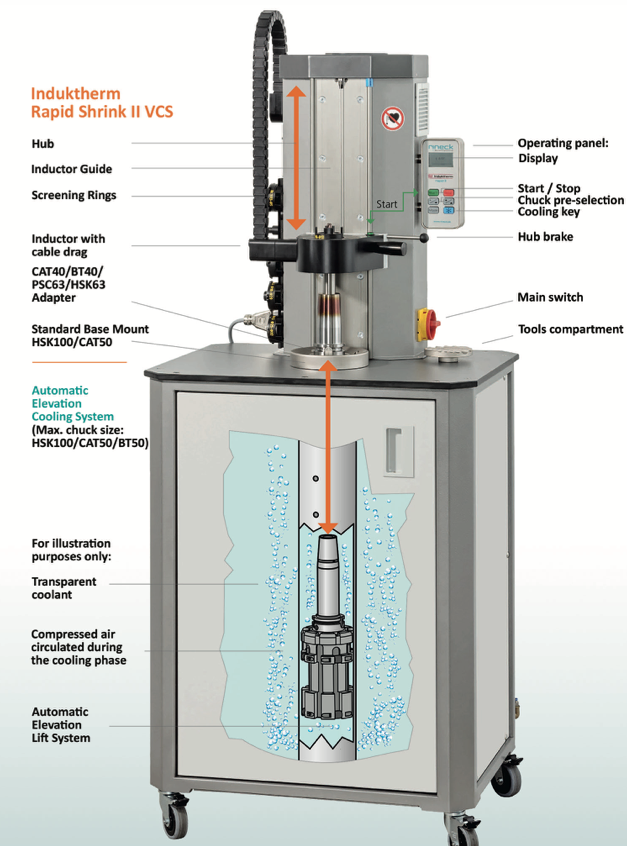

With the SPERONI ESSENTIA, you can efficiently measure tools, easily and independently of the operator achieving full machining productivity. Robust, space-saving, and long-lasting, ready to deliver quality results right beside your CNC machine. A leap forward in shrink-fit technology by Bernard Martin Platinum Tooling has introduced the Rineck Induktherm Rapid Shrink II VCS Machine to its repertoire, promising a paradigm shift in the way machining professionals approach shrink-fit tooling. In this article, we'll explore the key features, benefits, and applications of this cutting-edge machine that has garnered attention in the manufacturing industry.

Key Features of the Rineck Induktherm Rapid Shrink II VCS Machine: Rapid Heating Technology The Induktherm Rapid Shrink II VCS Machine is equipped with rapid heating technology, ensuring swift and efficient tool heating. This feature significantly reduces downtime and enhances overall operational efficiency. The heating time takes only between 3 – 9 seconds! Versatile Cooling System (VCS) The VCS system integrated into the machine allows for both air and water cooling, providing flexibility based on the specific requirements of different tools and materials. The cooling time varies between 15 and 50 seconds depending on the mass of the tool holder. User-Friendly Interface The machine boasts a user-friendly interface, making it easy for operators to navigate and control the heating and cooling processes. Intuitive controls contribute to a seamless user experience. Precision and Consistency The Induktherm Rapid Shrink II VCS Machine ensures precise and consistent tool clamping, critical for achieving accuracy in machining processes. This level of reliability is essential in applications where tolerances are tight. It's designed for use with HM tools with shafts of Ø 3 to Ø 32 mm and HSS tools of Ø 6 to Ø 32 mm Compact Design Despite its advanced features, the machine maintains a compact design, making it suitable for various workshop environments. Its space-saving attributes make it a versatile choice for machining facilities of different sizes. Benefits and Applications

Download CAD Drawings for you toolholders! Techniks is excited to announce that they are entering into a new stage of development for their website. Over the past several weeks Techniks has compiled 2D and 3D model files for each product available on www.techniksusa.com. That’s almost 4,800 total SKUs, 9,600 2D and 3D model drawings added for your convenience! The addition of downloadable CAD files is just the next phase in thier continued development of their site to improve its user-friendliness. You can now find your specific drawings through directly searching for the part number in the “Drawings” section of the main menu or by navigating directly to the product page. Simply navigate to the appropriate product table, locate the item you need, and click on the drawing file format you require. You will see a links to the 2D DWG and 3D STP files in the right-hand columns. Can’t find what you’re looking for?

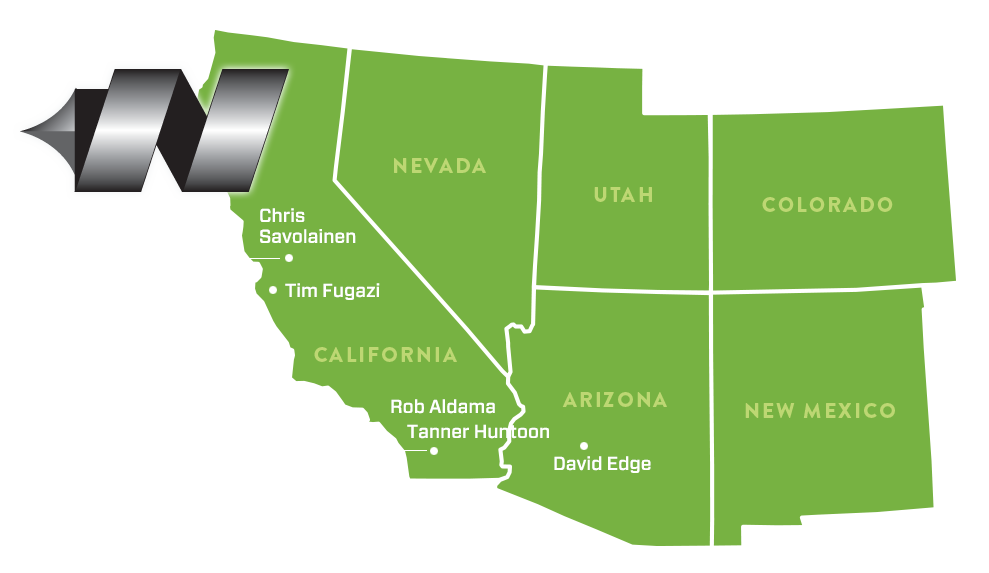

Techniks is adding more drawings every day, but if you do not find the drawings you need let them know at [email protected] and they'll prioritize your request to get you the drawings you need, FAST! As you begin to take advantage of their available CAD files, please don't hesitate to continue to provide feedback on your website experience to us and we can pass it along to Techniks. It’s been with your help that Techniks is able to provide the highest levels of customer service. A lot of that feedback comes form us passing along that information from you! Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

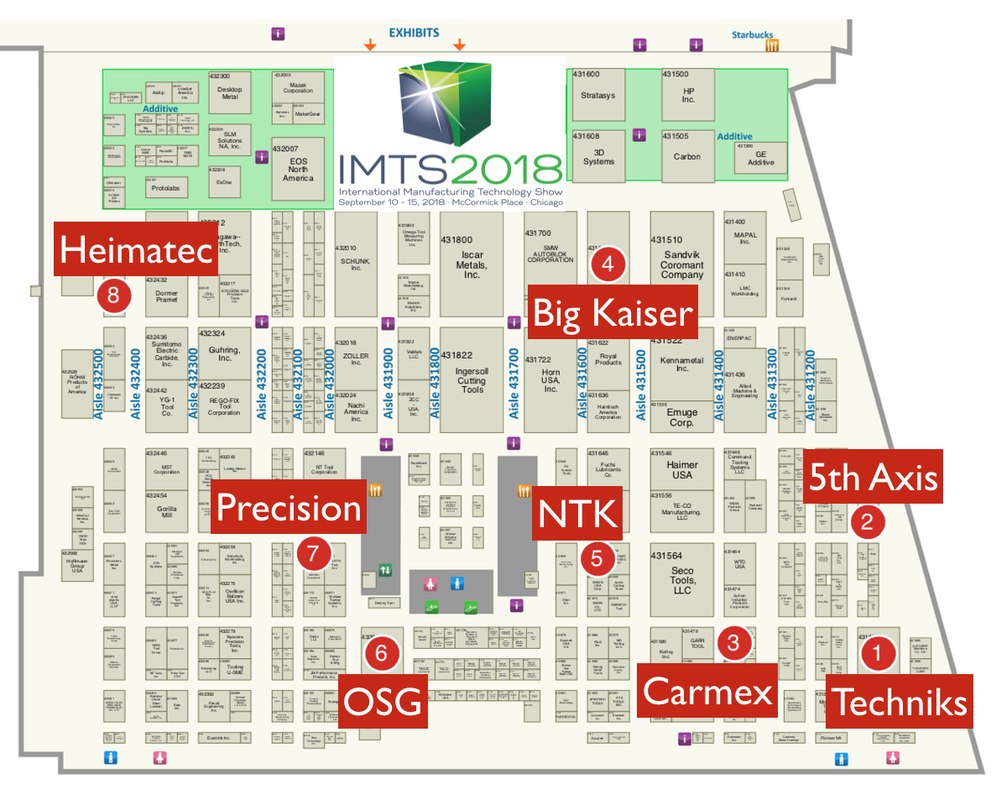

Join us at #IMTS2018! We'll be learning about new products at our principals booth. Check out our schedule, come join us and we'll learn some new things together! Wednesday September 12th

10:30 - 11:30 AM - NTK Cutting Tools Booth W-431664 1:00 to 3:00 PM - Big Kaiser Booth W-431610 Thursday September 13th 10:00 to 11:00 AM - Heimatec Booth W-433427 11:00 to 12:00 PM - 5th Axis Booth W-431158 1:00 to 2:00 PM - Precision Cutting Tools W-432164 Friday September 14th 10:00 to 11:00 AM - Carmex Booth W-431480 11:00 to 12:00 PM - OSG Booth W-432080 1:00 to 2:00 PM - Techniks Booth W-431075 Start measuring tools in less than 5 minutes! The STP MAGIS generation of tool presetting and measuring systems, from Big Kaiser, has revolutionized the value of entry level tool measurement. The innovative SimpleVision control delivers all of the needed measuring features and functions in a user friendly, clean and trouble free single screen user interface.

SAVINGS: $4,790.73 PROMO PACKAGE PRICE: $17,879.00 |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed