|

Here's a look at some of the new products and special offers from our manufacturers! You'll want to check them out in-person at the show, on-line during the show or contact us and we can stop in and get into the details at your shop with one of our guys. BIG DAISHOWA High-Performance Tooling SolutionsBIG DAISHOWA designs, manufactures and markets premium high-precision tooling systems and solutions for the automotive, military, aerospace, energy, and micro-technology industries. BIG DAISHOWA is the North American representative of Speroni tool measuring machines, Sphinx high performance drills, mptec measuring stands, Tekusa spindle cleaners and the UNILOCK zero-point workholding system Be sure and check out the two special offers:

Carmex Precision Tools, LLCCarmex Precision Tools specializes in carbide cutting tools for thread turning & thread milling. They will be showcasing a full line of tools for Swiss machines, including turning, back turning, grooving & parting. Jergens, Inc.Jergens Inc is a global manufacturing leader of CNC machining custom workholding products. Today, you'll find their vises, clamps & fixturing systems, tooling components, at work in just about every segment of the metalcutting industry. Check out their innovative engineered solutions like the patented

Platinum ToolingPlatinum Tooling has been hard at work searching to find the highest quality machine tool accessories in the market…and we think they’ve done it! Platinum Tooling will be showcasing the following products at IMTS:

Techniks Tool GroupTechniks Tool Group (TTG), the parent company of Techniks and Parlec, is one of North America’s largest providers of best-in-class tooling solutions for CNC machining centers. Check out the complete list of products they will be demonstrating at IMTS:

2 Comments

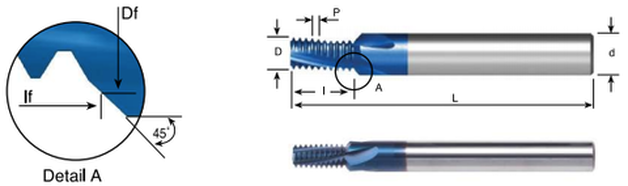

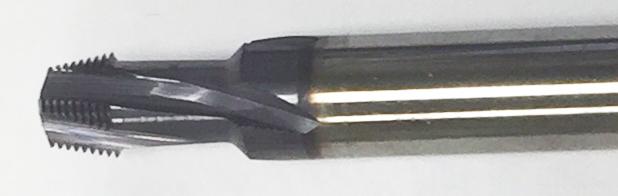

Carmex has introduced two new lines of multi-functional thread mills specifically for machining hardened materials up to 62 HRc. Engineered to meet threading challenges from ISO M1.4 x 0.3 and 0-80UN, HARDCUT thread mills deliver high performance in hardened steels, high-temperature alloys, Titanium alloys and ultra-hard formulations such as Hastelloy, Inconel, and nickel base alloys. Thanks to their short profile, they are capable of working at high cutting speeds, thereby shortening cycle times. The increased cutting diameter delivers better rigidity and stability, and the advanced PVD triple coating results in high wear and heat resistance and longer tool life.

The use of hard and super-hard materials in industries such as moldmaking, aviation, energy and medical implants and tools requires a new generation of thread mills capable of standing up to hard materials while, at the same time, delivering increased productivity through better performance and longer life. The Carmex HARDCUT line meets those demands through an extensive size range that delivers the Carmex guarantee of “X-TREME results.” The famous Vulcan greeting from Star Trek takes on a whole new meaning when it comes to tool life. This was recently proven at Apex CNC Swiss, a machine shop specializing in high precision complex parts machined from hard materials and alloys. According to Chuck Fluharty, co-owner of Apex, “We were machining an electronics circuit board standoff in 303 stainless on a Star SR-20RIII machine. The part required a 0.180" (4.6 mm) deep hole threaded with a 0-80 thread. At the time, we were working with tooling from a well-known German maker that delivered 200 to 300 parts before tool failure. We did not feel that this was acceptable and, when we contacted the manufacturer’s technical support, they advised that that performance was ‘normal.’ We immediately began to look for an alternative.” When Chuck and his team tried the Carmex mini mill-thread design, they saw production rise to more than 2,000 parts. More than that, they completed a further 500 parts in 17-4 stainless prior to failure.

Carmex performance at Apex CNC Swiss is another example of how tooling engineered for high performance and long life leads to greater prosperity for the customer. “Live Long and Prosper.”

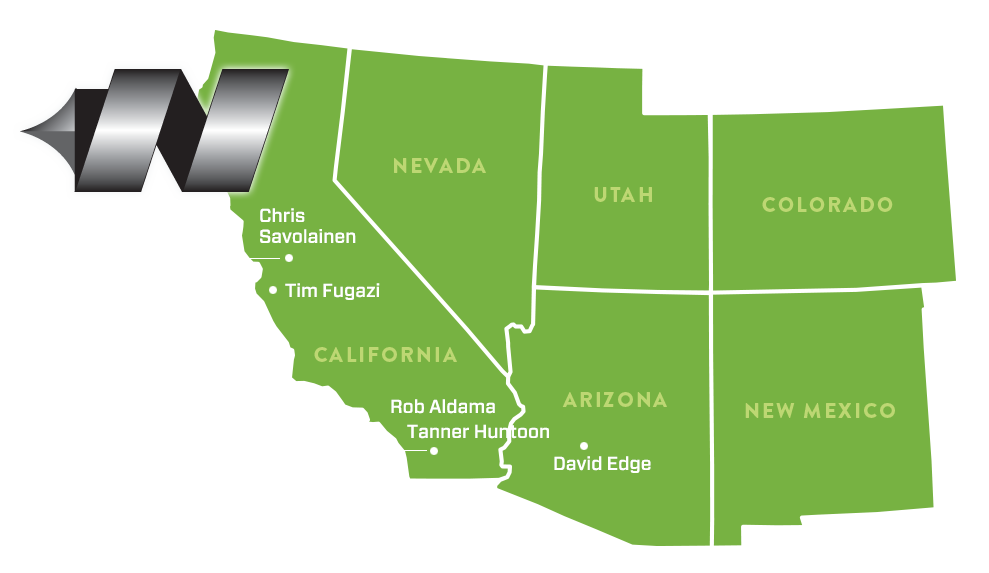

Sacramento, CA. - Next Generation Tooling, LLC, a manufacturer's representative agency, founded in 1995 and servicing the California Nevada Arizona, Utah, Colorado and New Mexico CNC manufacturing markets has just opened TWO offices in California. Most of Next Generation Tooling's customers know them as "the Next Gen guys" according to Chris Savolainen, the Founder and President of 'Next Gen Tooling'. What was the rationale of opening not one, but two offices when the entire team has worked out of their own home offices for years? "We've grown our market service area quite a bit since we started out servicing just Northern California. We now include most of the Western States of the US. We've s been adding some of the best technical CNC application people we can find to support the unique mix of principles we represent. The products that we represent are what are considered very high performance tooling and workholding. It's some of the premiere products in our entire industry! We determined that we really needed a place to provide on-site technical training. We also needed to carry some inventory to support the unique needs of the aerospace, medical, electronics and defense industries that we support." Said Savolainen. Rob Aldama, Vice-President of Next Gen Tool picks up the story, "At first we thought that one training and showroom might be good enough, but as we started talk to our distributor, machine dealer and end-user manufacturing customers, we discovered that there was a real need for facilities in both Northern and Southern California. None of our competitors are providing the deep technical service that has helped us gain market share, so we really felt we should just take it to the next level and open two facilities." But what about the Pandemic? With the Covid-19 pandemic raging there are not a lot of companies expanding. Most are cutting costs and employees. When asked about this both Chris and Rob stated that their team of people have remained pretty busy throughout this entire period. Chris said "We get asked in to shops to provide technical support pretty often. Putting on the full body PPE suits has been kind of common for us during the past few months." Rob picked it up from there, "I think we may be some of the really select few that have been asked to come into shops because we're not just taking orders, we're reducing cycle time and we're improving efficiency" Chris jumped back in, "And maybe its a little bit self serving, We can have the equipment set-up at both locations instead of trying to bring it into a facility. It's actually a lot easier, faster and safer to bring people to one of our locations rather than try to move things with lots of sweat and heavy breathing in PPE." "Yea, We can bring people to either location and do the training. There are far less interruptions and the I think people learn a lot more, and learn it faster" stated Rob. NGT Warehouse and Training What types of training do they provide at Next Gen's new buildings? They start off with a lot of fundamentals that people running CNC machines may never had any formal training about. That's where their basic Training Classes fit in.

But they also can go much deeper with their Advanced Part Manufacturing training series

Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations. Two new things for your this month from Carmex! The NEW FMT Thread mill and the NEW Double and Triple Start Tapered Thread Mills. Read below for the details! FOR IMMEDIATE RELEASE Carmex Precision Tools Richfield, WI., - Constructed of rugged MT8 carbide with Carmex’s exclusive BLU coating, the new FMT thread mill delivers accurate thread geometry and fine surface quality in short cycle times. Unlike conventional taps, the FMT can thread up to the bottom of a blind-hole while delivering the high reliability necessary for complex parts. FMT’s high-speed performance results from the increased number of flutes, which require an extremely heavy-duty carbide grade, as well as advanced coating technology in order to ensure a high degree of performance and longer tool life. In a recent test, an FMT thread mill with a 6-flute cutter and internal coolant created a 10mm internal right-hand thread to the bottom of a blind hole in SAE 4340 steel. The cycle time was 1.5 seconds and the tool life was 2,170 threads. In that test, and in any number of other applications, the FMT is emerging as the suitable thread mill for high-production/high-demand applications. NEW Thread Mills Designed for the Double- and |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed