Tim Fugazi joins the Next Generation Tooling team as Regional Manager in Northern California1/2/2020 Please welcome Tim Fugazi to our Next Generation Tooling team. Tim will be working in Northern California as Regional Manager for our principals. Tim graduated from San Joaquin Delta College with a Certificate in Computer-Aided Drafting December in 1999 and finished up his Associate Degree in Machine Tool Technology in May 2010 at the same college.

Tim spent 7 years as a Auto CAD Technician and then added Laser programming to the mix. For the past 18 years Tim has worked as a Machinist, SolidWorks Technician & Lab Technician. His experience with SolidWorks software was to provide mechanical drawings for production, fabrication and/or machining. He operated SolidWorks & HSMWorks software to produce “G” code for vertical mills and lathes as well as working in quality control and dealing with customer warranty issues. Our principals and distributors will be excited to know that Tim has a great understanding of shipping procedures so he has a great understanding of your capabilities and expectations.

0 Comments

David Edge David Edge We are very excited to announce that David Edge has joined the Next Generation Tooling team. David has a wealth of experience from his 45+ years in the metalcutting industry. He not only knows the technical aspects of cutting tool applications but also the procedural functions that are important to manufacturers, Industrial distributors and machinery dealers. David began his career in 1972 as a manufacturing engineer in turning applications, with Pneumatic Auto Turret lathes, Tracer lathes and manual Turret lathes. He cut his teeth in sales for 11 years as a cutting tool specialist for Valenite in the Bay area. He moved north to work for RTW and Iscar where he managed Washington, Oregon and Western Canada for the many aerospace applciations in that area. In 2012 he moved back to the Bay area to manage Northern California for Tungaloy. David also brings first hand experience as a distributor from his time at J&L Industrial Supply and Aronson-Campbell Industrial Supply as a carbide application engineer. He has a deep understanding of what the expectations are of a industrial distributor from a manufacturer. David also has an inside knowledge of the expectations of a machine tool dealer from his time back in the late 1980's working at Selway Machine Tools.

The International Manufacturing Technology Show is one of the largest industrial trade shows in the world, featuring 1,900 exhibitors and 100,000 visitors. The event is held every two years in September at McCormick Place, Chicago.

Don't miss out on the biggest show in Manufacturing - Register today! On-site registration is open Monday, Sept. 12 through Saturday, Sept. 17 in all four buildings of McCormick Place. Tooling & Workholding Systems Pavilion in the West Building is open 9:00 a.m. - 5:00 p.m. Several of our Principals will have products on display at IMTS 2016. Below is where you can find them at the show.

Pavilion: Tooling & Workholding Systems

Let us know if you're attending and let's make plans to meet each other in Chicago! Please welcome Matt Smith to the Next Generation Tooling Team! We are very pleased to announce that Matt Smith has joined our team.

Here's a quick overview of the newest tooling innovations we found at IMTS 2014. We've listed a short summary and some on-site video directly from the IMTS show floor. We'll be following up with more details on these great new manufacturing innovations in the next several months. The folks at Cutting Tool Engineering are really to be commended for creating many of the videos featuring the highlights of the hottest new products at IMTS 2014. Allied Machine & Engineering Corp. IMTS Booth: W-2034 Allied introduced and featured the Apex Line of Tools for large diameter Drilling at 3, 5 & 10X D. Also, if you haven't checked out the Instaquote online quoting and ordering tools. Check it out online! BIG Kaiser Precision Tooling Inc. IMTS Booth: W-1600 The Smart Damper deep hole boring system for finish boring & roughing and finish milling operations. The Smart Damper is a Tool Holder with Integrated Damping System for Deep Hole Finish Boring and Extended Reach Milling. Other new tool holders that where on display where the micro-tap and large-tap solutions in the Mega Synchro Tapping Holder series, the new Hydraulic Chuck Super Slim line, and the Mega Micro Chuck 8S. Heimatec Inc. IMTS Booth: W-2054 Heimatec was featuring their BMT tooling which is supplied with the company’s unique U-Tec® flexible machining system. It provides extremely high power transmission via polygonal drive. The Integrated collet nut, with easy changeout, can convert the output to arbor (for face mills), Weldon or ER collet extensions. They also featured their Z- Axis high-torque tool! See it in the video Milling hexagonal parts from 303 bar stock on a Miyano BNA42 GTY. MPower Workholding IMTS Booth: W-1916 A great video overview of the mPower products. They highlighted the unique self extracting feature of the SpeedLoc mounting system using a robot. They also displayed the ModLoc hollow tombstone technology so that hydraulic and pneumatic clamping comments can be installed internally. Also featured was the SpinLoc indexer for HMC's. Check out the video! NTK Cutting Tools IMTS Booth: W-1179 NTK introduced the new SiALON SX & Ceramic inserts for machining high temperature alloys. It has excellent wear resistance and reduces the cycle time by reducing the number of cutting passes required in these tough to machine materials. TechniksUSA IMTS Booth: W-1075 Techniks introduced their "game-changing inserts" to reduce wasted inserts & increase productivity. One insert for ALL materials. The LT1000 grade features their patented coating, making them harder & tougher than other brands, so you can use one insert for ALL materials. • Break-thru Swiss technology • 3.5x thicker coating • 250% longer tool lfe Allied Machine has just announced their newest product line, the APX™ Drilling System!! The APX is designed for depths beyond the range of a traditional IC drill. Allied's APX™ delivers the strength and versatility needed for any deep hole drilling application. The APX™ geometry is designed to increase penetration rates and tool life, providing the lowest cost per hole among deep hole drilling lines.

If you would like more information give us a call at 916.765.4227 or email us and we'll get you the catalog!

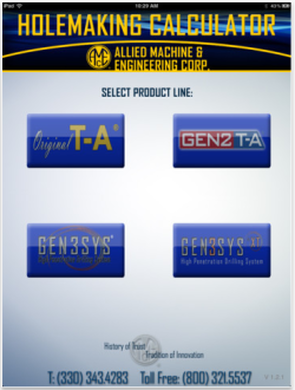

Have you seen the new App for drilling? If not you have to download this ASAP! The Allied Machine & Engineering Corp. HOLEMAKING Calculator is an easy-to-use guide that helps anyone efficiently run tooling, minimizing the chance for scrapped material or broken tooling. TheCalculator will prompt the user to input data (Tool Diameter, Spindle Drive, Material, etc.) and the calculator provides general machine requirements including horsepower, thrust, coolant pressure, etc. Product lines included in this app are: Original T-A® GEN2 T-A® GEN3SYS® GEN3SYS® XT Requirements: Compatible with iPad.Requires iOS 4.3 or later. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed