|

The famous actress Judy Garland is said to have adlibbed about fellow child-star Micky Rooney: "It's the little things that matter". For central Indiana based Greenwood Machine, little burrs in a 1mm slot, mattered a lot.

With 25 years in the business, Greenwood Machine's owner Fred McWilliams has loads of experience producing small, complex parts. His business began machining small, precision parts (primarily RF connectors) for the electronics industry, and has grown to include a variety of quick-setup, short run jobs, and also some high-end bicycle components. When the opportunity to manufacturer the air pump came up, Fred decided to move quickly and increase capacity by purchasing a bar-fed, Citizen/Cincom M32 CNC swiss-type turning machine to expedite production of the air pump. This configuration allowed them to perform 3 operations at once, giving them a big advantage in cycle time. Their customer asked that they produce prototypes within 3 weeks of the CNC machine hitting their floor. During the few weeks they had to set-up the machine and begin running prototypes, the deburring problem was discovered by Manufacturing Engineering Manager Joe Bowman. Joe's background includes experience with ISO 9001 certification and 8 years in CNC machining. He manages all the manufacturing processes even down to the CNC programs and setups.

The parts and pins are placed in a deburring container and media solution is added. Next, the container is put into the machine and the cycle time and rotation speed is set. While it runs the pins are activated by a rotating magnetic plate underneath the deburring container. This causes the pins to rapidly reverse polarity, and jump up and down from 1 to 3 inches while rotating in the deburring container along with the parts. The parts and pins "spin" together to perform the deburring. The sPINner can even deburr internal cavities like slots and cross-drilled holes other media cannot reach.

Michael Harris, Vice President at Earth Chain said: “The sPINner works best on small, precision parts made from non-ferrous metals including aluminum, brass, copper, stainless steel, and even titanium.” The aggressiveness of the deburring is controlled by programming the speed of the magnetic plate and selecting from a variety of media sizes. The machine is easily programmed and can run unattended.

1 Comment

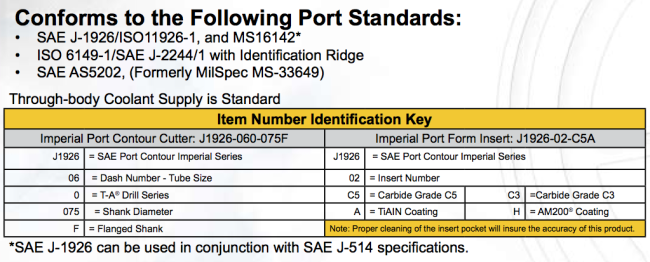

Allied Machine & Engineering has just announced the introduction of i6149 (Metric) style AccuPort 432 Port Contour Inserts made from C-3 carbide with AM200 coating. These inserts have the same geometry as the C-5 carbide TiAlN coated inserts which allows our customers to produce a finished port in one step! They are stocking both ridged & non-ridged configurations. Allied expects that the new C-3 AM200 coated porting tools should greatly improve tool life in gray iron manifold applications of up to 50% over their standard C-5 TiAlN inserts. You gotta love when companies like Allied who keep improving their own products when they're already a leader in the field! Here's how the part numbers work: |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

March 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed