|

by Doug Sumner, BIG DAISHOWA—Americas Successful shops always look for ways to differentiate and innovate for competitive advantage. Cashing in on the entirety of a tool’s life with an advanced tool management system is perhaps the most effective way to do that right now. Go with me for a minute. Think of a single tooling component’s trip through a shop in terms of a life: it’s conceived when it’s ordered from a supplier and born and finds its way to the tool crib; it grows up in the bin and finds its perfect mate when it’s assembled; it does good work on the job, cutting metal and eventually rides off into the sunset, aka the scrap bin. RIP tool. You lived a good life. All kidding aside, notice how little of the tool’s journey through the shop is spent actually cutting metal? As in life, one’s career is just one of many factors in a happy life. In this case, the actual time the tool is cutting accounts for a fraction of its impact on the shop. Acquisition, inventory management, assembly, travel across the floor, wear and dispensing of a tooling component, they all happen with a certain efficiency – or inefficiency – and have a value. Shops know how much of their purchasing budget goes to tooling, but few know how much value is gained or lost while it’s in the shop. This is where tool management systems (TMS) come in. Every company has a TMS of some sort, whether it’s the tool room manager’s chicken scratch on a printed excel sheet or wirelessly tracking components as they move across a shop and automatically managing inventory based on their usage. Based on my travels, the chicken scratch method, or some slight variation of it, is far more common today. But things are changing. The rise of Smart Manufacturing is exposing the immense savings available while the more connected floor is making them more accessible. It’s drawing a stark distinction between reactionary chicken scratch- and proactive hyper traceability-TMS. The risk of a reactionary system is finding out the value of the tool’s journey the hard way. Consider the following scenarios. A job makes its way from engineering and planning to the tool room. They discover they don’t have a certain insert or have just enough to start, but not to finish, and the stock sits until the insert arrives. That’s wasted spindle time, perhaps delayed delivery – maybe even paychecks – because of a missing insert that costs a few bucks. The other side of that coin is ordering more cutters just because the bin looks low and not having a job in the pipeline that requires them. That’s cash burning a hole in the tool shelves. If you have an offline tool measuring system, you’ve already taken the first steps toward more efficient tool management. Sure, tool presetters reduce setup time and tooling costs by eliminating error and adding precision, but now they can also act as a shop communication hub. Our most sophisticated, and frankly most consistently successful customers, use Speroni tool presetters equipped with software that communicates with the engineer’s CAM software to verify length, diameter, create a G-Code and post process with the exact tooling values. This type of arrangement is just scratching the surface. And believe it or not, suppliers have been working to get us to where we are for decades. Our Italian partner, Speroni, started working with Fiat automotive manufacturing more than 30 years ago, connecting tool rooms to the rest of the manufacturing facility. Today, most solutions are optimized for management, often without much flexibility to adapt to what’s happening on the floor or what may happen there next year. Having made our name in tooling – as far down in the weeds as you can get in a metalworking operation – we’ve worked with Speroni to apply a different philosophy to connectivity and traceability to our North American customers. Our solution, Intelligo, focuses on where everything is happening: the shop floor. Its processes are fed by using devices that recognize components, cutting edges, tool assembly, carts, baskets, etc. through wireless systems (i.e. RFID or QR/barcode) as they travel the shop. SPERONI INTELLIGO Tool Management Solution software allows you to comprehensively organize your tool assemblies, your individual components, plus your tool jobs and kits in a central knowledge database avoiding redundant data. Using a scalable software structure and local workstations, Intelligo links a company’s entire tool library, active or inactive, with the CAM, planning and measuring software and displays it in a 3D graphic interface for visual reference in real time. Visibility and tracking of the floor’s activity allows a shop to proactively manage consumable inventory, consumption and assembly, preventing downtime and enhancing profitability. You can monitor how tools wear on certain jobs and adjust. Or, if duplicate machines deliver different productivity on the same job, you can easily identify the exact tools used and find out what’s causing the discrepancy and diagnose machine or spindle issues. It’s even possible to determine a machine tool’s consumption in terms of discarded components following a particular production process. That’s not to mention the opportunity floor-up tracking and data provides to optimize tool regrinds, QA, raw material, fixturing – even the scrap bin, since it’s a profit center. This level of TMS may be a world away from how most manufacturers operate today, but for most it’s not that far out of reach. Installation is hands-on and cooperative, and most shops do have the fundamental infrastructure to support it. This train isn’t stopping. The technology is here, readily available and quickly making excuses like “it costs money and doesn’t make chips” or “this is the way we’ve always done it” obsolete. Shop and process connectivity is the direction metalworking is headed and I believe a floor-up approach is the best approach.

Now is the most profitable time to get on board, before everyone else is. Successful shops are always looking for ways to differentiate and innovate, and cashing in on the entirety of a tool’s life with advanced TMS is perhaps the most effective way to do that right now.

0 Comments

Next Generation Tooling, a leader in innovative machining solutions, is pleased to announce a new partnership with ARNO USA. Under this partnership, Next Generation Tooling will represent ARNO USA’s advanced cutting tools and machining solutions in California and Nevada.

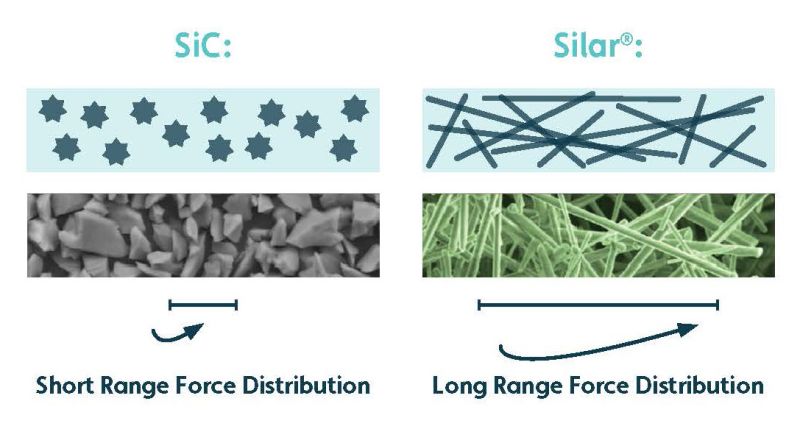

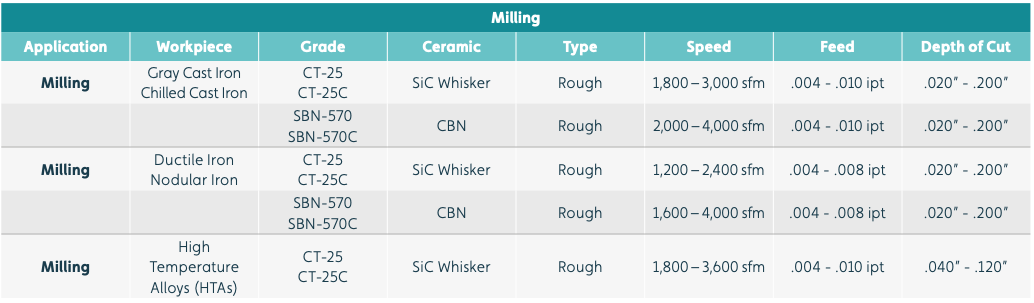

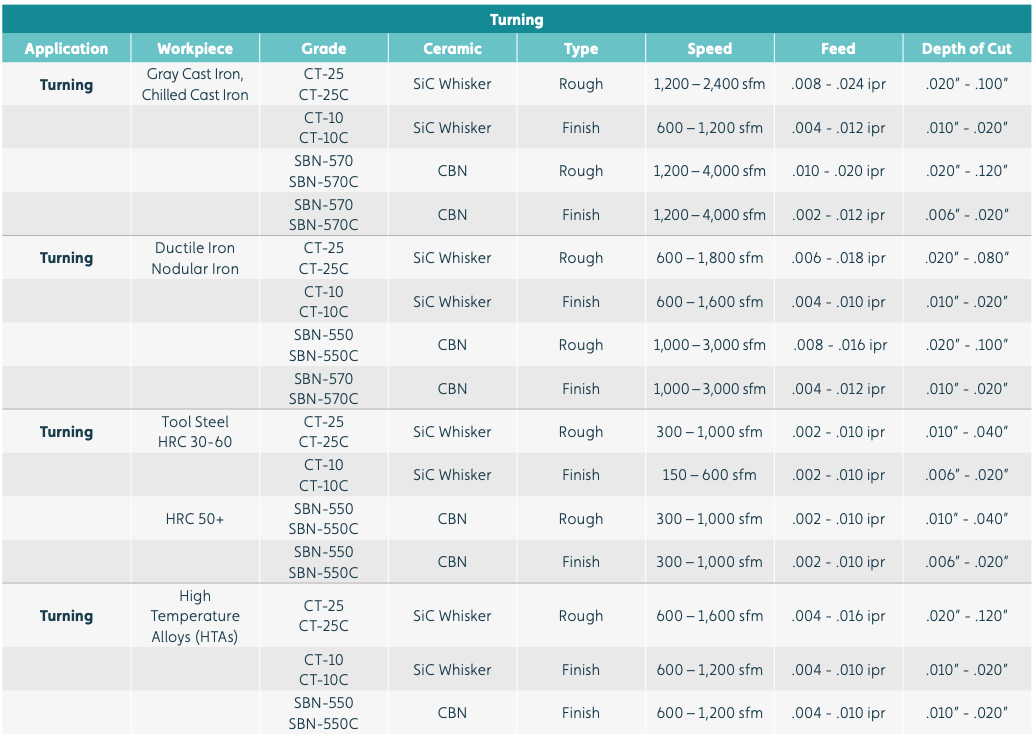

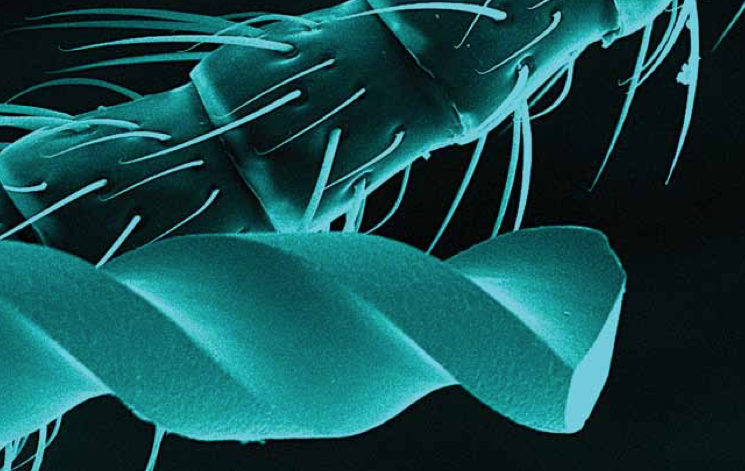

This strategic alliance is set to enhance the availability and support for ARNO USA’s high-quality products across key industrial markets in these states. Customers in California and Nevada can now benefit from the local expertise and support provided by Next Generation Tooling, ensuring they receive the most effective and latest technological advancements in tooling systems. “Partnering with ARNO USA aligns with our commitment to providing the best machining tools and support in the industry,” said Chris Savoliainen of Next Generation Tooling. “This collaboration not only expands our product range but also strengthens our service capabilities across California and Nevada.” ARNO USA is known for its innovation and excellence in the manufacturing of cutting tools. Next Generation Tooling will be organizing demonstrations across California and Nevada to showcase the comprehensive range of ARNO USA products. The selection of a ceramic cutting tool & grade is an important factor to consider when planning a successful metalcutting operation.  Haydale’s silicon carbide (SiC) whiskers reinforce ceramic inserts to deliver world-class hardness and fracture toughness. The inclusion of SiC provides hardness second only to diamond. Due to long range force distribution provided by the fibre, we are able to achieve this result while maintaining exceptional toughness. Ceramic cutting tools have excellent wear resistance at high cutting speeds and Haydale Ceramic Technologies (HCT), a world leading manufacturer of Silicon Carbide (SiC) ceramic materials, has the largest installed capacity for volume production across America, Europe and the APAC regions. HCT developed the world’s first whisker reinforced tools, and continues to lead in materials engineering and innovation in this category. Produced in Greer, South Carolina, their Silar® cutting tools are manufactured using the highest quality SiC products, particulate, fibers and microfibers. The inclusion of SiC whiskers provides hardness second only to diamond. Whisker-reinforced cutting tools offer both increased toughness and wear resistance, making them ideal for machining a variety of workpiece materials including Ni-based alloys, cobalt-based alloys, hardened steels, gray cast, ductile, nodular irons, and mill rolls. Cutting with reinforced or whiskered, ceramic inserts requires high surface speed and balanced feed rates. Enhanced Silicon Carbide Cutting ToolsHigh cutting forces and high heat cause the metal to plasticize while the Silar ceramic substrate remains in-tact. Whisker-reinforced cutting tools offer both increased toughness and wear resistance, making them ideal for machining a variety of workpiece materials including Ni-based alloys, cobalt-based alloys, hardened steels, ductile, and nodular irons, and mill rolls. Silar cutting tools are designed for heavy material removal in roughing and semi-finishing applications and offer the perfect solution for high-speed machining of heat resistant super alloys.

Aerospace Cutting ToolsAs demand for lightweight materials in the aerospace industry increases, Haydale can manufacture new grades and tooling that specialise in machining hard-to-cut materials. With higher speed and feed rates, Silar cutting tools deliver consistent results and longer life in applications for:

Silar® whisker reinforced ceramic cutting tools are designed for heavy material removal in roughing and semi-finishing applications. They offer the perfect solution for high-speed machining of heat resistant super alloys (HRSA) – Inconel, Waspalloy, Haynes, Monel, Rene, Incoloy, A-286, Nimonic, Udimet, etc. The Silar® CT-25 Grade offers a comprehensive and advanced range of high-speed cutting tool solutions while Silar SBN570 is a high-content CBN grade specifically designed for finishing Heat-Resistant Super Alloys (HRSA's). The high CBN content in SBN570 ensures superior cutting performance and extended tool life when dealing with these challenging materials. It can withstand the high temperatures generated during machining, allowing for efficient and precise finishing operations. Automotive Cutting ToolsIt is essential for turning and milling tools in automotive applications to wear evenly with minimal maintenance in the most demanding applications. To meet the workflow and high output demands, Haydale has a range of inserts for the automotive industry using SiC whiskers that are long-lasting and deliver consistent and reliable results as well as:

Steel Mill Cutting ToolsHaydale’s steel mill inserts offer an optimal choice for milling fracking blocks and for milling flats on mill roll necks. Steel mill geometries are used to remove heavy material in the most demanding rough turning conditions. Inserts are available for:

Haydale's Silar® inserts are designed for heavy DOC material removal in cast iron, compacted graphite iron (CGI), ductile iron, nodular iron, hardened steels (transmission components), white iron, chilled iron, and powdered metals.

If you would like to determine if Silar Ceramic cutting tools are right for your application, get in contact with us! OSG is pleased to announce the expansion of our PHOENIX® PDZ offering with the addition of the NEW PDZ-3D indexable flat drill.

The following list numbers are associated with the OSG PHOENIX® PDZ Series Expansion:

The PHOENIX® PDZ indexable flat drill offers the following features & benefits:

Performance Micro Tool's Unprecedented Advancements in End Mills and Cutting-Edge Applications3/13/2024 Performance Micro Tool first to make the world's first 5 micron end mill. Today, Performance Micro Tool end mills are approaching diameters and tolerances thought impossible just a few years ago. Their unique manufacturing ability has led to many firsts including the world's first 5 micron end mill. PMT's in-stock and custom end mills are used in some amazing applications - from designing medical diagnostic tools for use inside the body to developing micro components for U.S. fighter jets. The PMT product line and unique quality controls assure customers of superior end mill performance and longevity. They also offer the shortest lead times in the industry! PMT Features

PMT Applications

OSG is pleased to announce the expansion of our HY-PRO® CARB VGM end mill series with the addition of the NEW VGM3-AL!

The HY-PRO® CARB VGM3-AL is a is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials. The following list numbers are associated with the NEW VGM3-AL series:

The HY-PRO® CARB VGM3-AL end mill offers the following features & benefits:

Entry-level Tool Presetting and Measuring system Big Daishowa’s Speroni STP Essentia tool presetting and measuring system performs measurements next to machine tools. The SPERONI STP ESSENTIA is the entry-level Tool Presetting and Measuring system. Its robust structure and user-friendly software interface allow customers to benefit from a basic, essential unit with a tangible, long-lasting performance. The ESSENTIA enables users to measure tools offline and has user-friendly controls designed to optimize tool measurement operations. The MaxP runout function, base post processor and entry-level tool database are included in the Essentia control. Presetters measure the cutting edges of tools to ensure they match job specifications and are ready for use in the machine. Adjustments that could take up to 15 minutes can be made offline in less than one minute on a presetter, the company says, allowing the machine to continue cutting.

With the SPERONI ESSENTIA, you can efficiently measure tools, easily and independently of the operator achieving full machining productivity. Robust, space-saving, and long-lasting, ready to deliver quality results right beside your CNC machine. |

NEWSOur NEWS blog section is written by several different people. Sometimes, it from our team here at Next Generation Tooling & at other times it's by one of the manufacturer's we represent. Archives

July 2024

Categories

All

|

About

|

© 2024 Next Generation Tooling, LLC.

All Rights Reserved Created by Rapid Production Marketing

|

RSS Feed

RSS Feed